How Many Under Cabinet Lights Do I Need?

Share

Table of Contents

Introduction

Quick answer: count fixtures by coverage. For a 10‑ft run, use about 4 linear bars (24–36‑in segments) for continuous coverage, or ~12 puck lights spaced ~10‑in along the front. Verify ~30–50 fc on the counter.

The number of under cabinet lights should match your run lengths, fixture type, and target brightness at the countertop. Use continuous coverage for linear bars and consistent spacing for pucks, then verify illuminance for clear, comfortable results.

Table: Coverage and Spacing by Fixture Type

| Fixture Type | Primary Rule | Typical Spacing / Coverage | Notes |

|---|---|---|---|

| Linear bars/strips | Continuous coverage | Use segment lengths to cover the full run; avoid diffuser gaps > 1 inch | Set 1–2 inch setback from the front lip; prefer frosted/opal diffusion |

| Puck lights | Even spacing | Space ~8–12 inches center‑to‑center along the front | Use more pucks near sinks/corners to fill shadow pockets |

| Utility/night runs | Low output, uniform guidance | Lower density; keep paths evenly lit | Motion sensors reduce energy and maintain comfort at night |

Detailed Analysis

Factors Influencing the Number of Under Cabinet Lights

-

Cabinet Length and Layout

The length and layout of your cabinets play a crucial role in determining the number of lights needed. Longer cabinets require more lights to ensure even illumination across the entire countertop.

-

Type of Lighting Fixture

The type of lighting fixture—whether linear bars or puck lights—also affects the number of lights required. Linear fixtures typically cover more area per light compared to puck lights, which are smaller and more focused.

-

Desired Illumination Level

The desired brightness and uniformity of lighting can influence the number of fixtures. For task lighting, more lights may be needed to eliminate shadows and provide sufficient illumination.

Professional Guidelines and Data

Illuminance targets (industry practice)

Size fixture count to meet on‑counter illuminance rather than a fixed “lights per inch” rule. Task zones commonly target roughly 30–50 footcandles (≈ 325–540 lux), with lower levels for ambient scenes. Verify at the counter after placement.

Spacing and placement (practical rules)

- Linear bars: choose segment lengths to achieve continuous coverage; keep diffuser gaps ≤ 1 inch.

- Puck lights: space ~8–12 inches center‑to‑center; add units near sinks and corners.

- Set fixtures 1–2 inches behind the front lip to project light onto the workspace and reduce backsplash glare.

Practical Calculation Example

Consider a 10‑foot (120‑inch) continuous cabinet run along the front lip.

Linear bars

- Target task illuminance at the counter: ~30–50 fc.

- Select segment lengths (e.g., 12, 18, 24, 36 inches) to cover ≈ 120 inches with diffuser gaps ≤ 1 inch.

- Example coverage: 36 + 36 + 24 + 24 = 120 inches → 4 bars, continuous coverage.

- Verify with a phone lux app: aim for ≈ 325–540 lux at prep zones; adjust output or diffusion as needed.

- Set scenes: brighter for prep, lower for evenings; ensure low‑end dimming is stable.

- Count outcome: 4 linear fixtures for the 10‑foot run.

Puck lights

- Space pucks ~10 inches center‑to‑center along the front.

- Count = ceil(120 / 10) = 12 pucks for even coverage.

- Verify illuminance at the counter and add a puck near sinks/corners if shadows persist.

Real-World Applications

Residential Kitchen Example

In a residential kitchen with 8 feet of cabinets, the homeowner opted for linear LED fixtures spaced 16 inches apart. This setup used 6 fixtures, providing even lighting across the countertop. The homeowner noted an improvement in visibility during cooking and meal prep, with no dark spots or shadows.

Commercial Workspace Example

A commercial kitchen with 15 feet of countertop used puck lights for targeted task lighting. Placing puck lights 10 inches apart resulted in 18 lights, ensuring bright and even illumination. This arrangement improved the chefs' ability to perform detailed tasks and enhanced overall kitchen efficiency.

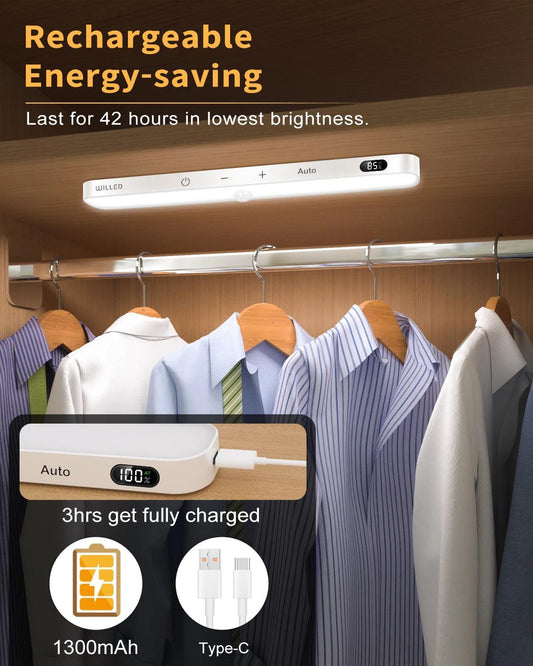

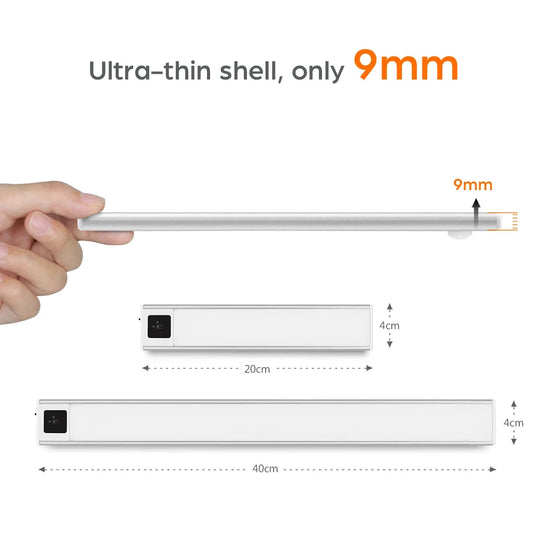

In a residential kitchen, where even lighting is essential, the Touch & Hand Sweep Sensor Under Cabinet LED Light Bar provides an excellent solution. With its ultra-thin design and no-drill installation, it can be easily integrated into your kitchen setup. The touch and hand sweep sensors make it convenient to adjust the lighting, ensuring that the entire countertop is well-lit with minimal effort.

Conclusion

Determine fixture count by coverage and spacing rules, then confirm on‑counter illuminance. Continuous linear coverage or evenly spaced pucks, front placement, and diffusion deliver clarity without glare.

References

- Illuminating Engineering Society — Illuminance definitions. ies.org/definitions/illuminance

- ENERGY STAR — Lighting program overview. energystar.gov/products/lighting_fans/lighting

Further Reading

Explore the full guide for this topic: Light Quality for Under Cabinet Lighting: Color, Brightness & Comfort

/>

/>

/>

/>

/>

/>

/>

/>

/>

/>