Kitchen task & undercabinet LED lighting: layouts, fixtures, and installation tips

Share

Table of Contents

- Task lighting layout and illuminance targets

- Undercabinet fixture types and trade-offs

- Color quality metrics and dimming compatibility

- Power, wiring, and code considerations

- Installation methods and mounting details

- Controls, sensors, and zoning strategies

- Maintenance, heat management, and longevity

- Cost estimation and budgeting rules

Task lighting layout and illuminance targets

Countertop work zones generally require 300–500 lux (30–50 fc) on the task plane; plan fixture placement and lumen output to meet those targets with minimal glare. Use lumen-area calculations and overlapping beam patterns to eliminate dark spots and ensure consistent task illuminance.

Implementation details: - Target illuminance: 300–500 lux (30–50 foot-candles) for food prep; 150–300 lux (15–30 fc) for general circulation and sinks. - Quick lumen rule: required lumens = desired lux × task area (m²). For imperial: lumens = foot-candles × area (ft²).

Practical layout rules: - Spacing: place linear fixtures or strips so their beam spreads overlap by ~20–30% to avoid scalloped lighting; with a 60° beam, spacing-to-mounting-height ratio ≈ 1.2:1. - Mounting depth: recess or set tape/strip 6–12 mm back from cabinet face to reduce direct glare while maintaining even wash on the counter. - Zoning: separate undercabinet runs by logical task area (prep, stove, sink) to allow independent control and varied intensity.

Design checklist (two quick lists): 1) Measurement list before buying fixtures: - Measure counter length and depth. - Mark cabinet overhang and reveal height. - Identify junction box or nearest power source. - Note existing dimmer type (triac, 0–10V, smart hub). 2) Quality metrics to target: - CRI ≥ 90 for accurate food colors. - CCT 2700–3500K for warm kitchens, 3500–4000K for neutral/modern. - Minimum 300 lm/ft for true task-level illumination in most kitchens.

Undercabinet fixture types and trade-offs

Choose between linear bars, LED tape, puck lights, and modular spot systems based on run length, desired uniformity, and installation access. Each type has trade-offs in cost, serviceability, and light quality.

Comparison table (approximate typical values and trade-offs):

| Type | Lumens per foot | Typical CRI | Dimming ease | Best use | Trade-off |

|---|---|---|---|---|---|

| Linear LED bar | 300–1000 lm/ft | 80–95+ | Good with compatible drivers | Continuous, even wash for long runs | Higher cost; needs mounting depth |

| LED tape (12V/24V) | 150–800 lm/ft (model dependent) | 80–95+ | Depends on driver; PWM best | Flexible runs, hidden installations | Voltage drop over long runs; requires channel for dissipation |

| Puck lights | 200–600 lm per puck | 80–95 | Moderate; often on low-voltage drivers | Accent lighting or small work areas | Can create scalloped pools, more fixtures needed |

| Modular fixture (spots) | 300–1000 lm per module | 80–95+ | Good with specified drivers | Task-focused illumination and adjustable aim | Less even wash; may cast shadows |

Selection decision rules: - For runs >8–10 ft, prefer 24V tape or continuous linear bars to reduce voltage drop. - For highest color fidelity (food prep, plating), insist on CRI ≥ 90 and TM-30 information if available. - For visible installations where finish matters, choose integrated aluminum channels with frosted diffusers for even light and thermal management.

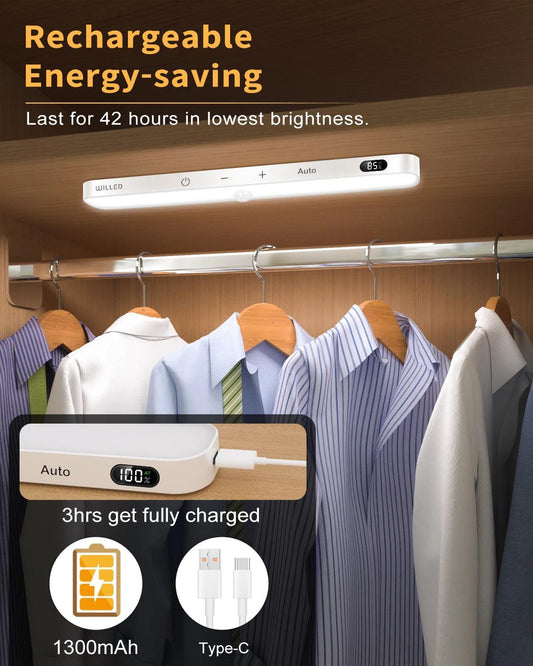

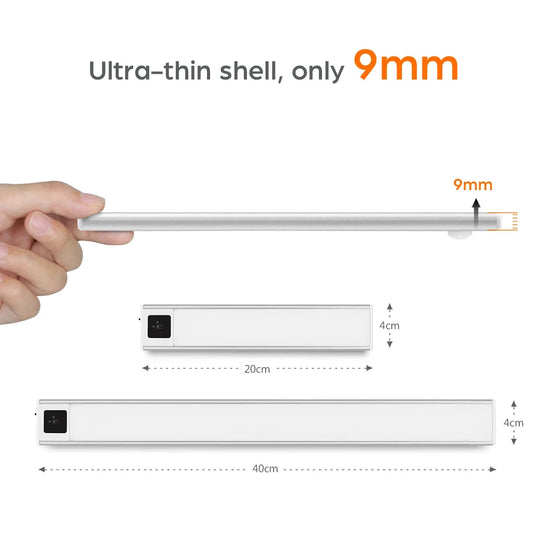

Ultra-thin Touch Sensor Under Cabinet LED Light Bar for Kitchen Wardrobe Lighting

Color quality metrics and dimming compatibility

Color rendering (CRI) and color temperature (CCT) determine perceived food and surface color; choose CRI ≥ 90 and CCT between 2700K–3500K for most kitchens. Confirm dimmer-driver compatibility to avoid flicker and color shifts.

Implementation guidelines: - CRI: select fixtures rated CRI ≥ 90 for accurate reds (meat, tomatoes) and subtle color tones. Lower CRI (80–85) flattens color rendering. - CCT: 2700–3000K for warm traditional kitchens, 3000–3500K for balanced white light, 3500–4000K for bright contemporary looks. - Dimming: identify your control type (forward-phase/TRIAC, reverse-phase, 0–10V, PWM). Buy LED drivers explicitly marked compatible with your dimmer type to prevent flicker. Smart bulbs/drivers may require manufacturer-specific hubs.

Technical note: LED diodes can shift correlated color temperature and chromaticity when dimmed; high-quality drivers preserve tint through the dim range. ENERGY STAR and DOE guidance explain energy and quality trade-offs for LED selection: ENERGY STAR: Learn about LEDs and DOE: LED Lighting.

💡 For lighting that’s both beautiful and adaptable, choose Lumaz. Our advanced LEDs deliver superior color quality and seamless dimming for a smarter, brighter experience.

Power, wiring, and code considerations

Self-Adhesive COB LED Under Cabinet Lights Touch Dimmable Silica Gel Neon Tape Lights

Decide between plug-in and hardwired installations, choose voltage (12V vs 24V vs line-voltage), and respect transformer capacity and run-length limits to avoid voltage drop and code violations. Hire an electrician for any new branch-circuit work.

Key metrics and rules: - Transformer sizing: sum tape or fixture wattages and add 20% buffer; do not size a transformer to more than 80% of capacity for continuous loads. - Voltage drop: for 12V systems, keep run length low (typical useful max 8–10 ft without upsizing wire); 24V systems allow longer runs (20–30 ft) before significant drop. - Circuit requirement: kitchen countertop receptacles must be on dedicated 20A small-appliance circuits per NEC, but undercabinet lighting is typically on lighting circuits—confirm with a licensed electrician and local code.

Tools and parts list for electrician/hands-on DIY: - Multimeter and non-contact voltage tester. - Appropriate LED driver/transformer with thermal protection. - Junction boxes sized per code and wire connectors rated for LED low-voltage. - Fire-rated cable routing and clips; conduit if required by local code.

Safety and compliance note: always follow local building codes and the National Electrical Code (NEC) for circuit protection and junction box access; improper wiring creates fire hazard and negates manufacturer warranties.

Installation methods and mounting details

Install LED strips or bars in aluminum channels with diffuser, secure power connections inside accessible junction boxes, and seal penetrations to prevent heat buildup. Proper mechanical fastening and thermal path extend lifespan and reduce glare.

- Plan runs and mark centerline on the underside of the cabinet; confirm spacing from backsplash to control glare.

- Mount channels or fixture brackets using screws into cabinet substrate; avoid nailing directly into thin cabinet bottom without reinforcement.

- Wire drivers/transformers in an accessible cabinet space or above cabinets; use proper strain reliefs and junction boxes.

- Connect LED leads, test for even light and flicker before finalizing mounting; secure diffusers to avoid sagging.

- Label circuits and leave an access panel or removable cover for future driver replacement.

Installation tips: - Use aluminum channel for tape lights to act as a heat sink; adhesive tape alone is insufficient for long-term thermal management. - When running cables through cabinet bottoms, use grommets and keep low-voltage wires separate from line-voltage where feasible. - For retrofits where screw mounting is not possible, choose high-bond foam tapes rated for mounting and temperature range, but prefer mechanical fastening when achievable.

💬 "Replacing our old undercabinet fluorescents with high-CRI LED strips made chopping and color-matching a night-and-day difference—no shadows, no humming." — homeowner review

Controls, sensors, and zoning strategies

Ultra-thin USB Under Cabinet LED Light Bar Rechargeable Motion Sensor for Kitchen Cabinet

Group undercabinet lighting into 2–4 control zones per kitchen run and use dimming or smart-scene controls to optimize usability and energy. Select control protocols compatible with fixtures and the household ecosystem.

Zoning rules and control options: - Typical zones: main prep run, sink/stove, island, toe-kick/ambient. Aim for no more than 10–12 ft per zone for flexible control. - Control methods: line-dimming (triac/ELV) for simple installs, 0–10V or DALI for commercial-grade control, and Zigbee/Z-Wave/Wi‑Fi for smart-home scenes. - Sensors: motion or ambient-light sensors are practical for quick-on tasks; ensure sensor placement avoids false triggers from oven heat or window light.

Implementation checklist for smart integration: - Match fixture driver to control protocol (e.g., choose an ELV-compatible driver for common wall dimmers). - Use load-shedding scenes (e.g., 30% ambient + 100% task) to balance energy and visibility. - Include master control near prep zone and optional remote/app control for dimming and color temperature if tunable-white fixtures are used.

Maintenance, heat management, and longevity

LED lifespan depends on junction temperature and driver quality; plan for L70-rated lifetimes around 35,000–50,000 hours and design for driver accessibility and adequate heat dissipation.

Maintenance and longevity guidance: - Expect typical LED modules to reach L70 (70% of initial lumen output) between 35,000 and 50,000 hours depending on thermal conditions and driver stress. - Thermal management: use aluminum channels and avoid enclosing drivers in non-ventilated tight spaces. Elevated cabinet temperatures shorten LED and driver life. - Cleaning: wipe diffusers with a soft cloth and mild detergent; avoid harsh solvents that degrade plastics.

Service checklist: - Annual: check for flicker, dimmer compatibility, and discoloration. - At 25–30k hours: plan budget for driver replacement or module refresh if lumen output falls significantly. - Keep spare drivers/LED modules and label wiring for quick swaps.

Cost estimation and budgeting rules

Estimate total cost by summing fixture price per foot, driver cost, and labor; use a simple payback model based on fixture wattage, hours of use, and local electricity rate to evaluate ROI.

Ballpark numbers and calculation method: - Typical product costs: LED tape or basic bars $8–$20 per foot; premium high-CRI fixtures $20–$60 per foot. - Labor: electrician rates vary; budget $75–$150 per hour and 2–6 hours for typical retrofit installs depending on complexity. - Energy calculation example: annual kWh = watts × hours/day × 365 ÷ 1000. Savings = (old wattage – new wattage) × hours/year × $/kWh.

Example ROI: - Old fluorescents and halogens (120 W equivalent) replaced by 18 W LED per linear foot, used 3 hours/day. - Annual energy saved per fixture-foot = (120–18) W × 3 h/day × 365 /1000 ≈ 111 kWh/year. - At $0.15/kWh, annual savings ≈ $16.65 per foot; simple payback = fixture cost per foot ÷ annual savings.

Use ENERGY STAR and DOE resources to refine savings and product selection: ENERGY STAR LED guide and DOE LED lighting advice.

FAQs

Can I run different CCTs on the same undercabinet run?

Technically yes, but avoid mixing CCTs on the same continuous run because small color differences are highly visible; instead zone by CCT so each switch controls a uniform color temperature.

Are low-voltage 12V LED strips safer than line-voltage fixtures?

Low-voltage reduces shock risk but introduces voltage-drop limitations and requires a transformer; safety depends on installation quality and code compliance, so consult an electrician.

Do undercabinet LEDs need GFCI protection?

GFCI requirements depend on local code and whether the circuit serves countertop receptacles; lighting circuits are typically not on the countertop GFCI circuits, but check local regulations and inspector guidance.

Can I retrofit into shallow cabinet bottoms?

Yes—use ultra-low-profile linear bars or tape inside a slim aluminum channel; ensure driver placement has ventilation and that adhesive mounting is rated for the substrate and temperature.

Will LEDs show fingerprints or shine on glossy countertops?

High-CRI, diffused fixtures reduce specular reflections; position lights slightly toward the backsplash and use frosted diffusers to minimize mirror-like glare on glossy surfaces.

Is professional installation worth the cost?

For new circuits, complex dimming/smart integration, or when cutting into cabinetry or dealing with line voltage, a licensed electrician is recommended to ensure safety, code compliance, and warranty preservation.

Related Articles:

- Install & Replace Puck Lights: Ceilings & Cabinets

- Wireless Under-Cabinet Lighting: Options & Tips

- Puck Lights with Remote Control Guide

- Choose the Right Under-Cabinet LED Lighting

- Puck Lights vs Other Lighting: Full Comparison

- LED Light Bars: Benefits for Under-Cabinet Tasks

- Under-Cabinet Lighting Buying Guide

/>

/>

/>

/>

/>

/>

/>

/>

/>

/>