What Kind of Wire Do You Use for Under Cabinet Lighting?

Share

Table of Contents

- Introduction

- What Kind of Wire Do You Use for Under Cabinet Lighting?

- Understanding Wire Gauge

- Types of Wire Insulation

- Factors to Consider When Choosing Wire

- Expert Opinions and Data

- Practical Examples and Personal Experiences

- Conclusion

- FAQs

Introduction

When installing under cabinet lighting, selecting the appropriate wire is crucial for safety and functionality. The best kind of wire for under cabinet lighting is typically 18 gauge wire, which offers a balance between flexibility and current capacity. However, the specific type of wire may vary depending on the voltage, current requirements, and installation conditions. Let's explore the details, supported by expert insights and practical examples.

What Kind of Wire Do You Use for Under Cabinet Lighting?

For most under cabinet lighting installations, 18 gauge wire is recommended. It provides sufficient current capacity for LED lights, is flexible for easy routing, and is durable enough for long-term use. In certain situations, 20 gauge or 16 gauge wire may be appropriate based on specific needs.

Understanding Wire Gauge

Wire gauge indicates the diameter of the wire. The American Wire Gauge (AWG) system is commonly used, where a lower number indicates a thicker wire capable of carrying more current.

20 Gauge Wire

- Best For: Short runs, low power LED strips.

- Details: 20 gauge wire is thin and flexible, suitable for short distances and low current applications. It is easy to handle but may not be adequate for longer runs or higher power requirements.

18 Gauge Wire

- Best For: Most under cabinet lighting installations.

- Details: 18 gauge wire strikes a good balance between flexibility and current-carrying capacity. It is commonly used for LED lighting, providing enough capacity for typical under cabinet setups without being too bulky.

16 Gauge Wire

- Best For: Longer runs, high power LED strips.

- Details: 16 gauge wire is thicker and can carry more current over longer distances without significant voltage drop. It is less flexible than thinner gauges but provides greater reliability for demanding installations.

| Gauge | Best For | Current Capacity | Flexibility |

|---|---|---|---|

| 20 AWG | Short runs, low power LEDs | Low | High |

| 18 AWG | Most under cabinet installations | Moderate | Moderate |

| 16 AWG | Long runs, high power LEDs | High | Low |

Types of Wire Insulation

THHN (Thermoplastic High Heat-Resistant Nylon-Coated)

- Best For: Hardwired installations.

- Details: THHN wire is suitable for dry and wet locations. Its high heat resistance makes it ideal for environments where temperature control is essential. The nylon coating adds extra durability.

Romex (NM-B)

- Best For: Residential installations.

- Details: Romex wire is commonly used in residential wiring. It is easy to work with and provides good protection for indoor applications. It is not suitable for wet or outdoor locations.

Low Voltage Wire

- Best For: Low voltage LED lighting.

- Details: Low voltage wire is designed specifically for systems operating below 50 volts, such as many LED lighting setups. It is typically more flexible and easier to install in tight spaces.

| Insulation Type | Best For | Key Features |

|---|---|---|

| THHN | Hardwired installations | High heat resistance, durable |

| Romex (NM-B) | Residential installations | Easy to work with, good protection |

| Low Voltage | Low voltage LED lighting | Flexible, easy to install |

Factors to Consider When Choosing Wire

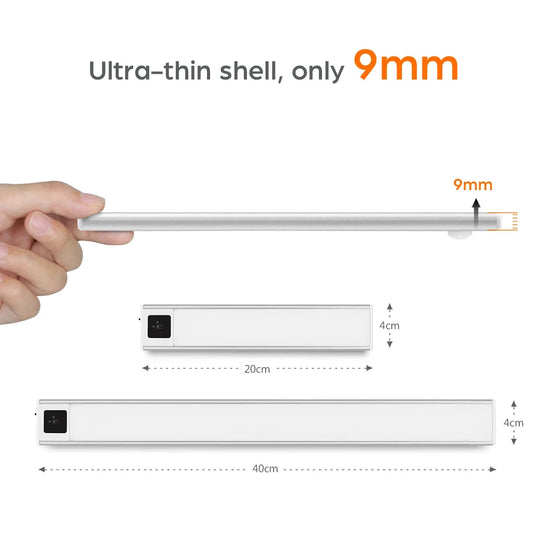

Tuya Zigbee Smart Under Cabinet LED Puck Lights with Dimmable Full Kit For Kitchen Closet

Voltage Rating

Ensure the wire you select is rated for the voltage of your lighting system. Low voltage LED systems (12V or 24V) have different requirements than standard 120V systems.

Current Capacity

Choose a wire gauge that can handle the current draw of your lighting setup. Overloading a wire can lead to overheating and potential fire hazards.

Flexibility and Ease of Installation

Consider the physical flexibility of the wire, especially for installations in tight or complex spaces. Thinner gauges and specialized low voltage wires are generally easier to work with.

Expert Opinions and Data

- National Electrical Code (NEC): The NEC provides guidelines for safe electrical installations, emphasizing the importance of using the correct wire gauge and insulation type for specific applications.

- Illuminating Engineering Society (IES): The IES recommends considering both current capacity and voltage drop when selecting wire for lighting installations, ensuring that the chosen wire can handle the load without significant performance loss.

Practical Examples and Personal Experiences

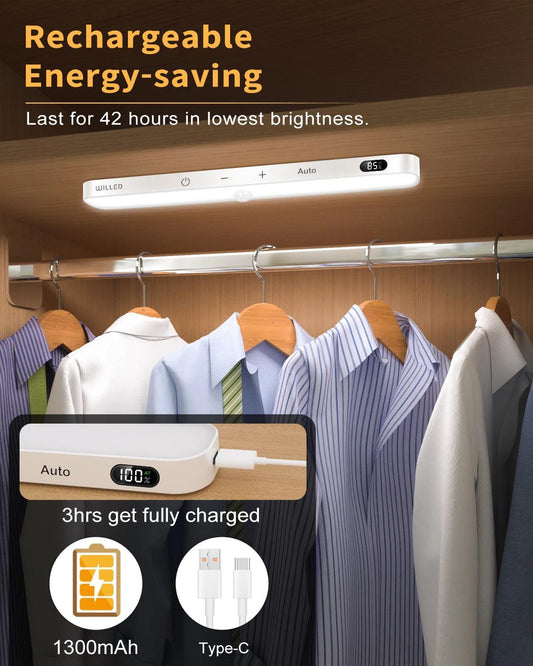

Dimmable Under Cabinet COB LED Strip Lights with Hand Touch Motion Sensor Switch

Example 1: Kitchen Renovation with 18 Gauge Wire

In my own kitchen renovation, I used 18 gauge wire for the under cabinet LED strip lights. The wire was flexible enough to navigate through the cabinets and provided sufficient current capacity for the lighting setup. The installation was straightforward, and the lights have been functioning perfectly.

Example 2: Workshop with 16 Gauge Wire

For a friend’s workshop, we opted for 16 gauge wire to power high output LED bar lights. The longer runs required the thicker wire to prevent voltage drop. While less flexible, the 16 gauge wire ensured reliable performance and adequate power delivery.

Example 3: Low Voltage Lighting in a Home Office

In a home office project, we used specialized low voltage wire for 12V LED puck lights. The wire was easy to route through the cabinets and provided a neat, professional installation. The low voltage setup minimized the risk of electrical issues.

Conclusion

In conclusion, the best kind of wire for under cabinet lighting is typically 18 gauge wire, offering a balance between flexibility and current capacity. For specific needs, such as longer runs or higher power requirements, 16 gauge or 20 gauge wire may be more appropriate. Additionally, selecting the right insulation type—such as THHN for hardwired installations or low voltage wire for LED systems—is crucial for ensuring safety and performance. By following these guidelines and considering expert advice, you can ensure a successful and reliable under cabinet lighting installation.

Explore our range of motion sensor under cabinet lighting solutions at Lumaz to find the perfect fit for your kitchen.

FAQs

What gauge wire is recommended for under cabinet lighting?

18 gauge wire is generally recommended for most under cabinet lighting installations. It provides a good balance of flexibility and current capacity. For longer runs or higher power needs, 16 gauge wire may be more appropriate.

What type of wire insulation is best for under cabinet lighting?

THHN and Romex (NM-B) are good choices for hardwired installations. Low voltage wire is ideal for low voltage LED lighting systems, providing flexibility and ease of installation.

Do I need a specific type of wire for low voltage LED lighting?

Yes, using specialized low voltage wire is recommended for systems operating below 50 volts. This wire is designed to handle the lower voltage and is typically more flexible for easy installation.

Why is wire gauge important for under cabinet lighting?

Wire gauge affects the current-carrying capacity and voltage drop of the wire. Choosing the correct gauge ensures that your lighting system receives adequate power without overheating or performance loss.

Can I install under cabinet lighting wire myself?

Yes, many under cabinet lighting installations can be done as DIY projects. However, for hardwired systems or if you are unsure about electrical work, it is advisable to hire a professional to ensure safety and compliance with electrical codes.

Further Reading:

/>

/>

/>

/>

/>

/>

/>

/>

/>

/>