Moisture-Resistant Under Cabinet Lighting for Sinks & Wet Areas

Share

Table of Contents

- What is moisture-resistant under-cabinet lighting?

- Which rating for sinks, bathrooms, and outdoor kitchens?

- Fixture types: LED strips, linear bars, pucks, and recessed for wet locations

- Materials and corrosion resistance: what holds up in humid and salty environments?

- Electrical safety, codes, and GFCI requirements

- Installation best practices for sinks, bathrooms, and outdoor kitchens

- Power, dimming, and control options for moist environments

- Maintenance, troubleshooting, and lifecycle expectations

- Buying checklist and specification templates for contractors and homeowners

- Frequently asked questions (FAQ)

- Conclusion

What is moisture-resistant under-cabinet lighting?

Moisture-resistant under-cabinet lighting is LED or low-voltage lighting designed and rated to withstand humidity, splashes, and outdoor exposure near sinks, showers, and grills.

Under-cabinet lighting placed near sinks, in bathrooms, or in outdoor kitchens must resist moisture, corrosion, and occasional direct spray. These fixtures use sealed housings, silicone gaskets, and appropriate ingress protection (IP) ratings to prevent electrical faults and premature failure. Beyond safety, moisture-rated fixtures maintain light quality (CRI, color temperature) in demanding environments and reduce maintenance cycles.

IP ratings and protection levels: which rating for sinks, bathrooms, and outdoor kitchens?

Choose an IP rating based on exposure: IP44 for splash resistance, IP65 for direct spray, IP67/IP68 for immersion — match rating to location and local electrical codes.

Ingress Protection (IP) codes define how well a fixture resists solids and water. The two-digit code (e.g., IP65) matters when selecting fixtures for wet or damp spaces:

- First digit (0–6): protection against solids and dust.

- Second digit (0–9): protection against moisture (splashes, jets, immersion).

Quick guidance:

- Sinks & general bathroom counters: minimum IP44 (protection against splashing water).

- Areas near shower heads, open-air outdoor kitchens exposed to rain/spray: IP65 (protected against water jets).

- Fixtures that may be submerged or exposed to standing water: IP67 or IP68 (temporary or continuous immersion).

IP rating comparison table

| IP Rating | Meaning | Typical Use | Recommended For |

|---|---|---|---|

| IP20 | No water protection | Indoor dry areas only | Not for sinks/bathrooms |

| IP44 | Protection against solid objects >1mm and splashes | Bathroom counters, above-sink lighting | Sinks, vanity lighting (indirect exposure) |

| IP65 | Dust-tight, protected against low-pressure water jets | Outdoor kitchens, shower-adjacent fixtures | Outdoor cabinets, near sprinklers, shower surrounds |

| IP67 / IP68 | Temporary / continuous immersion | Fixtures occasionally submerged or waterproof connectors | Floor-level lighting near water features |

Fixture types: LED strips, linear bars, pucks, and recessed for wet locations

Select fixture type by space, desired beam, and maintenance: low-profile sealed strips for counters, IP65 linear bars for outdoors, and recessed waterproof for under wet cabinets.

Fixtures that work well in moist environments share sealed designs and corrosion-resistant materials. Common options:

- Sealed LED strip lights: Flexible or rigid strips in silicone or epoxy channels — excellent for continuous task light; pick IP65+ for outdoor use.

- Linear LED bars: Rigid, high-output modules with aluminum housing and gasketed lens — ideal for high-lumen needs and direct-mount under cabinets.

- Puck lights (sealed): Round small fixtures good for accent/task spots; choose IP44+ and silicone seals if near sinks.

- Recessed mini fixtures: Installed into cabinetry bottoms with waterproof mounting and sealed wiring for premium look and greater splash protection.

Fixture selection quick checklist

- Confirm required IP rating for the exact location.

- Choose appropriate lumen output (see “Power & lumen guidance” section).

- Prefer integrated LED modules with replaceable drivers over non-serviceable fixtures.

- Check manufacturer wet-location listing and warranty for damp/wet use.

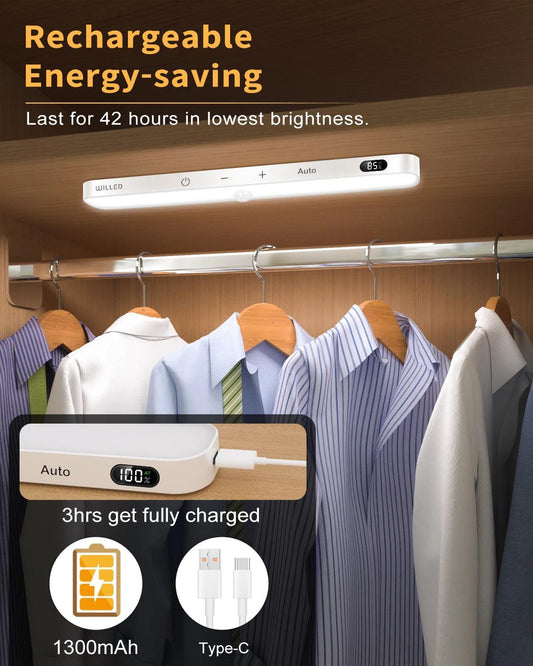

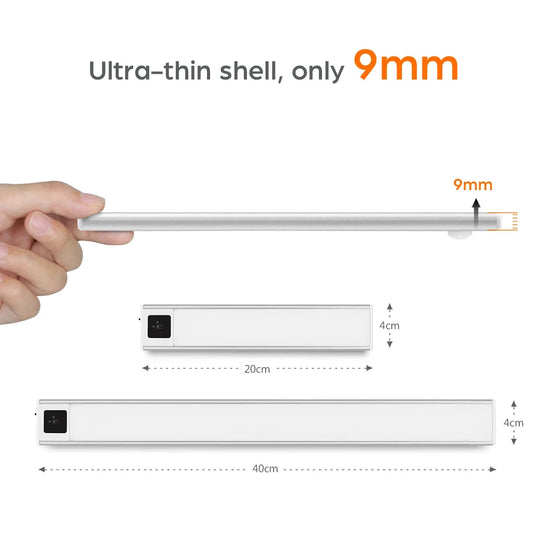

For wet locations like sinks and kitchens, the Moisture-Proof Under Cabinet LED Light Bar offers reliable, waterproof, and dustproof performance. Its super-bright illumination ensures clear visibility while remaining resistant to moisture and splashes, making it perfect for wet environments.

Materials and corrosion resistance: what holds up in humid and salty environments?

Materials and finishes determine lifespan in moist spaces — choose aluminum or stainless steel housings, silicone lenses, and marine-grade connectors for salt exposure.

Selection of materials influences durability and safety:

- Housings: Anodized aluminum dissipates heat and resists corrosion; marine-grade stainless steel is best for very salty environments.

- Lenses & seals: UV-stable polycarbonate or silicone lenses resist yellowing; EPDM or silicone gaskets maintain long-term seals.

- Connectors & fasteners: Use stainless hardware and IP-rated, gel-filled or silicone-filled connectors outdoors.

For coastal outdoor kitchens, prioritize “marine” or “salt-spray” ratings in product specs to avoid accelerated corrosion and electrical failures.

💡 For lasting performance in damp spaces, choose fixtures built to resist corrosion. Lumaz uses premium, sealed materials for reliable, worry-free lighting.

Electrical safety, codes, and GFCI requirements

Follow NEC and local codes: GFCI protection for bathroom and kitchen receptacles, proper low-voltage driver placement, and sealed connections reduce shock risk.

Key safety points:

- Most jurisdictions require Ground-Fault Circuit Interrupter (GFCI) protection for bathroom and kitchen receptacles; under-cabinet lighting tied to those circuits should comply with local code.

- Low-voltage systems (12V/24V) still require safe, sealed drivers with proper ventilation, and wet-location drivers where specified.

- All field wiring must follow the National Electrical Code (NEC) and local amendments; when in doubt, hire a licensed electrician.

For general electrical safety guidance, consult the U.S. Department of Energy’s LED lighting basics and OSHA’s electrical safety pages:

Installation best practices for sinks, bathrooms, and outdoor kitchens

Proper mounting height, sealed wiring, and correct driver placement ensure safe, long-lasting installations in wet areas.

Follow a stepwise approach to installation:

- Plan layout: map outlets, driver locations, and cable runs to minimize exposed connections.

- Select fixtures with the required IP rating for their exact mounting point.

- Mount drivers and junctions away from direct water and in ventilated, accessible locations; use in-line waterproof enclosures if needed.

- Use waterproof connectors and heat shrink or silicone potting at any exposed splices.

- Test with a GFCI and continuity tester before closing up cabinetry.

Special considerations:

- Maintain a small gap or drip edge where lights meet cabinetry to prevent water from pooling above fixtures.

- Seal screw penetrations with silicone where necessary to protect cavity from moisture.

- For retrofit installations under existing cabinets, route wiring through access holes near the cabinet interior, not through the cabinet bottom where water may drip.

Power, dimming, and control options for moist environments

Use properly rated drivers, moisture-tolerant dimmers, and smart controllers designed for damp locations to maintain performance and safety.

Power and control choices affect usability and longevity:

- Driver selection: Choose constant-current or constant-voltage drivers matched to the LED type; for wet installations, use drivers rated for damp/wet locations or place drivers in protected areas.

- Dimming methods: 0–10V and DALI offer robust control for commercial projects; triac (leading/trailing edge) dimming is common residentially but must be compatible with LED drivers.

- Smart controls: Wi‑Fi or Zigbee controllers can be used if the device and its power supply are installed in dry, ventilated enclosures; use moisture-rated switches outdoors.

Tip: If you expect frequent moisture exposure, choose electronically simple drivers and avoid electronics next to direct water paths. Verify dimmer-driver compatibility with manufacturer charts to prevent flicker.

Maintenance, troubleshooting, and lifecycle expectations

Regular cleaning, visual checks of seals, and quick replacement of degraded drivers extend service life; expect 30,000–50,000 hours from quality LED fixtures.

Maintenance and diagnostics:

- Inspect seals and mounting hardware every 6–12 months; replace degraded gaskets promptly.

- Clean lenses with mild soap and a soft cloth; avoid harsh solvents that break down silicone or coatings.

- Troubleshoot flicker by checking for loose connectors, driver overheating, or dimmer incompatibility.

Typical lifespans and ROI:

- High-quality LEDs: 30,000–50,000 hours (10–15 years typical residential usage).

- Energy savings: LEDs use ~70–80% less energy than incandescent and 30–50% less than halogen equivalents — see DOE LED guidance for efficiency metrics.

- Replacement considerations: factor in driver warranty and ingress protection — a higher initial cost for IP65+/marine-rated fixtures often lowers lifecycle cost by reducing replacements.

🔧 "Installed IP65 linear bars under our outdoor bar cabinets last summer — no corrosion after one rainy season and cleaning is easy. Worth paying extra for the seals." — Community installer review

Buying checklist and specification templates for contractors and homeowners

Use a concise spec checklist to compare products: IP rating, lumen output, CRI, CCT, driver location, warranty, and corrosion resistance.

Printable spec checklist (use when evaluating products):

- IP rating (min): _______ (record required rating for location)

- Luminous flux (lumens per foot or fixture): _______

- Color temperature (CCT): _______ (recommended 2700–3000K for warm, 3000–4000K for task)

- Color Rendering Index (CRI): _______ (≥90 for accurate color in bathrooms/kitchens)

- Driver type & location: _______ (wet-rated or mounted in dry enclosure)

- Dimming compatibility: _______ (list compatible dimmer models)

- Material & finish: _______ (anodized aluminum, stainless steel, etc.)

- Warranty & corrosion/salt-spray rating: _______

- Manufacturer wet-location listing and installation instructions: attached? Yes / No

Quick purchase tips

- Buy fixtures with clearly stated wet-location listings and IP numbers—if unclear, request technical data sheets.

- Prefer fixtures with replaceable drivers and documented dimmer compatibility.

- When budgeting, include costs for waterproof connectors, gaskets, and professional electrician labor if required by code.

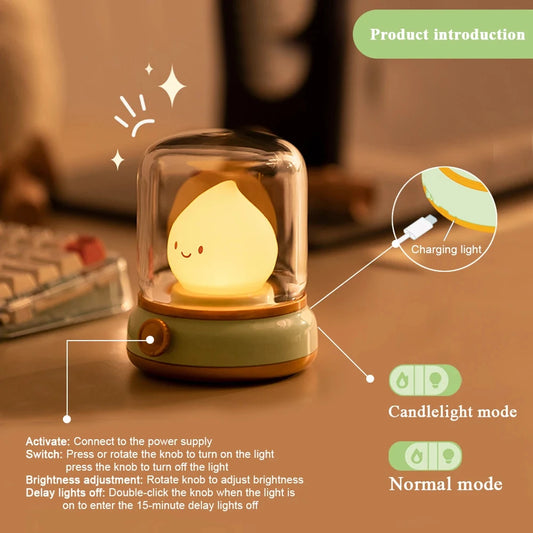

For a reliable and waterproof lighting option, consider the Penetrating Touch Sensor USB Under Cabinet COB LED Strip. With its IP67 rating, dimmable functionality, and hand scan feature, it's perfect for wood and glass surfaces, offering both durability and convenience for contractors and homeowners alike.

Frequently asked questions (FAQ)

Practical answers for common buyer and installer questions about moisture-resistant under-cabinet lighting.

Do I always need an IP65 fixture under a kitchen cabinet that’s near a sink?

No—not always. If the fixture is mounted under the cabinet and will only experience occasional splashes, IP44 is often sufficient. For direct spray, open-air outdoor kitchens, or fixtures exposed to rain, choose IP65 or higher.

Can I use a regular indoor LED strip in a bathroom if it's mounted high and away from water?

Only if local codes allow it and the fixture location is classified as "dry." For most bathroom installations, using a damp- or wet-rated fixture (IP44+) is the safer, code-compliant choice.

How bright should under-cabinet lighting be for kitchen prep and bathroom tasks?

Aim for task illuminance of roughly 300–500 lux on work surfaces. Practically, that often means 300–700 lumens per linear foot for under-cabinet runs, depending on mounting height and beam angle.

Are low-voltage systems safer in wet areas?

Low-voltage (12V/24V) reduces shock risk but doesn't eliminate the need for proper sealing, rated drivers, and GFCI protection where required. Always follow code and manufacturer guidance.

How do I prevent condensation inside under-cabinet fixtures in humid climates?

Use fixtures with venting designed for humid environments or desiccant-filled housings where appropriate; ensure seals are intact and minimize temperature differentials that drive condensation.

When should I call a licensed electrician?

Call a licensed electrician for any new hardwired installation, circuit changes, driver relocations, or when local code requires licensed work. If you’re uncertain about GFCI protection or run new wiring through wet areas, get professional help.

Conclusion: Practical next steps for safe, long-lasting under-cabinet lighting

Match IP rating to exposure, choose corrosion-resistant materials, install drivers safely, and maintain seals to ensure durable under-cabinet lighting around sinks, bathrooms, and outdoor kitchens.

Action plan:

- Survey your site and determine exposure level (splash, spray, immersion).

- Select fixtures with the appropriate IP rating and corrosion-resistant materials.

- Plan driver placement in dry, ventilated areas and use GFCI-protected circuits as required by code.

- Document product specs and keep manufacturer instructions for future maintenance.

Following these steps will improve safety, reduce lifetime cost, and deliver consistent, high-quality light where you need it most. For technical reference on LED performance and safety, see the U.S. Department of Energy’s guidance on LEDs and OSHA's electrical safety resources.

Further Reading

Explore the full guide for this topic: Under Cabinet Lighting for Any Home Space: Kitchens, Shelves, Desks, and Cabinets

/>

/>

/>

/>

/>

/>

/>

/>

/>

/>